ND100 Experimental Microfluidizer Nano Disperser

ND100 Experimental Microfluidizer Nano Disperser

Brand: UK Microfluidizer Nanotechnology Limited

Model: ND-series Nano Disperser

Manufacturer: OEM

ND 100 Experimental High Pressure Microfluidizer Nano Disperser

Product Summary

The high pressure dispenser enables PCB control, which is highly convenient, and controls pressure and flow by adjusting the speed of the motor / Compact design for transport

Overview

Compact design | User convenience | High safety

Application field

Used for various research purposes

ND100 实验型高压微射流纳米分散机

产品概要

本高压均质机支持PCB控制,操作便捷,通过调节电机转速实现压力与流量的精准控制/紧凑型设计便于运输

产品特点

紧凑结构 | 操作便捷 | 安全可靠

应用领域

适用于多种科研用途

Series | Operation pressure | Flow rate | Pump system | Weight | Dimension (W x D x H) | Interaction Chamber Size | Interaction Chamber Size |

ND100 | 1,500 bar | 100 ml/min | Motor driven type [220 VAC, 1 PH, 60 Hz, 1 HP] | Approx. 45kg | 583 x 576 x 435 | 75um | Z type |

Detailed description

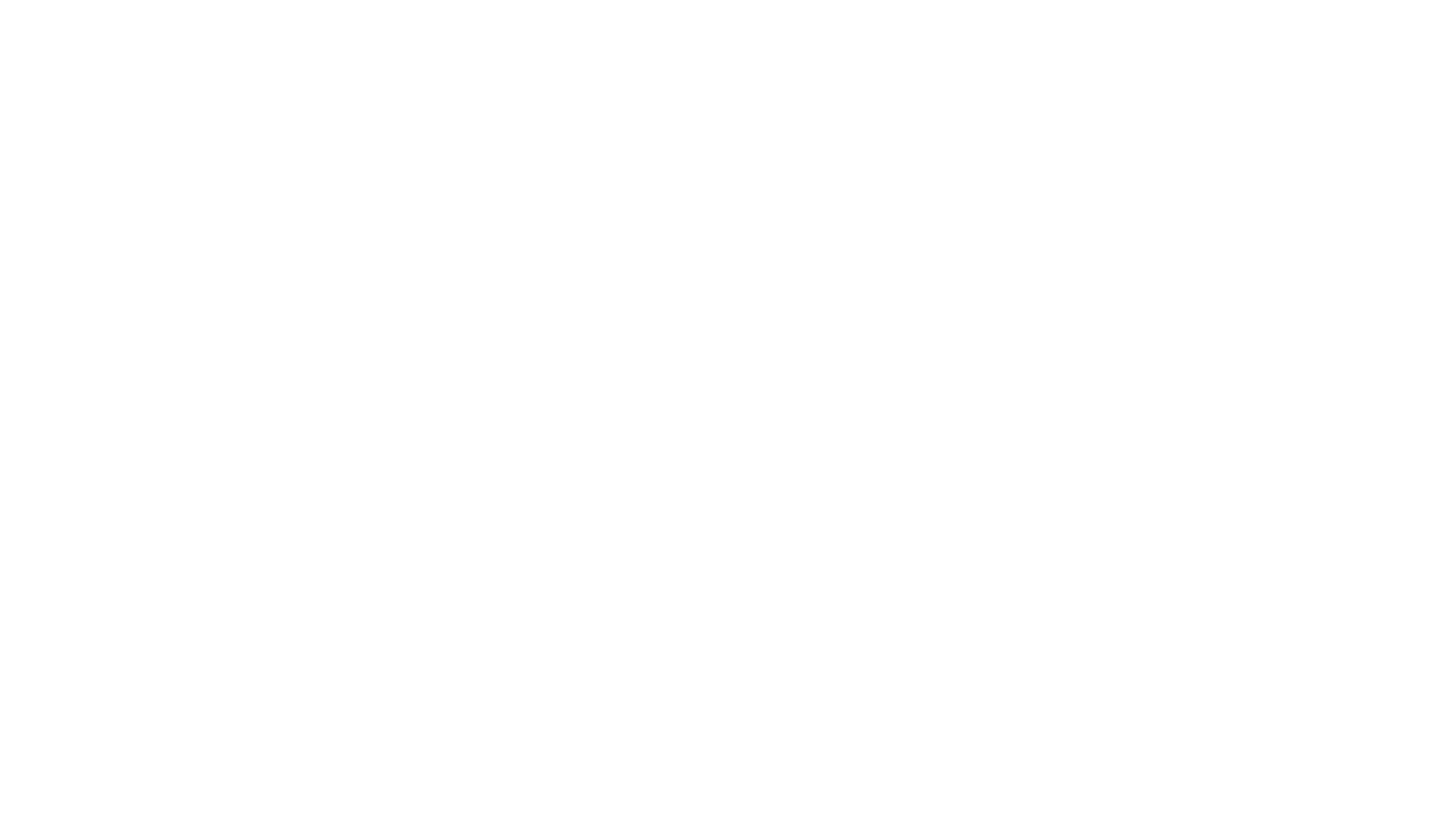

Composition specialized with long-standing know-how and technical skills

详细描述

具有长期专业知识和技术技能的专业构造

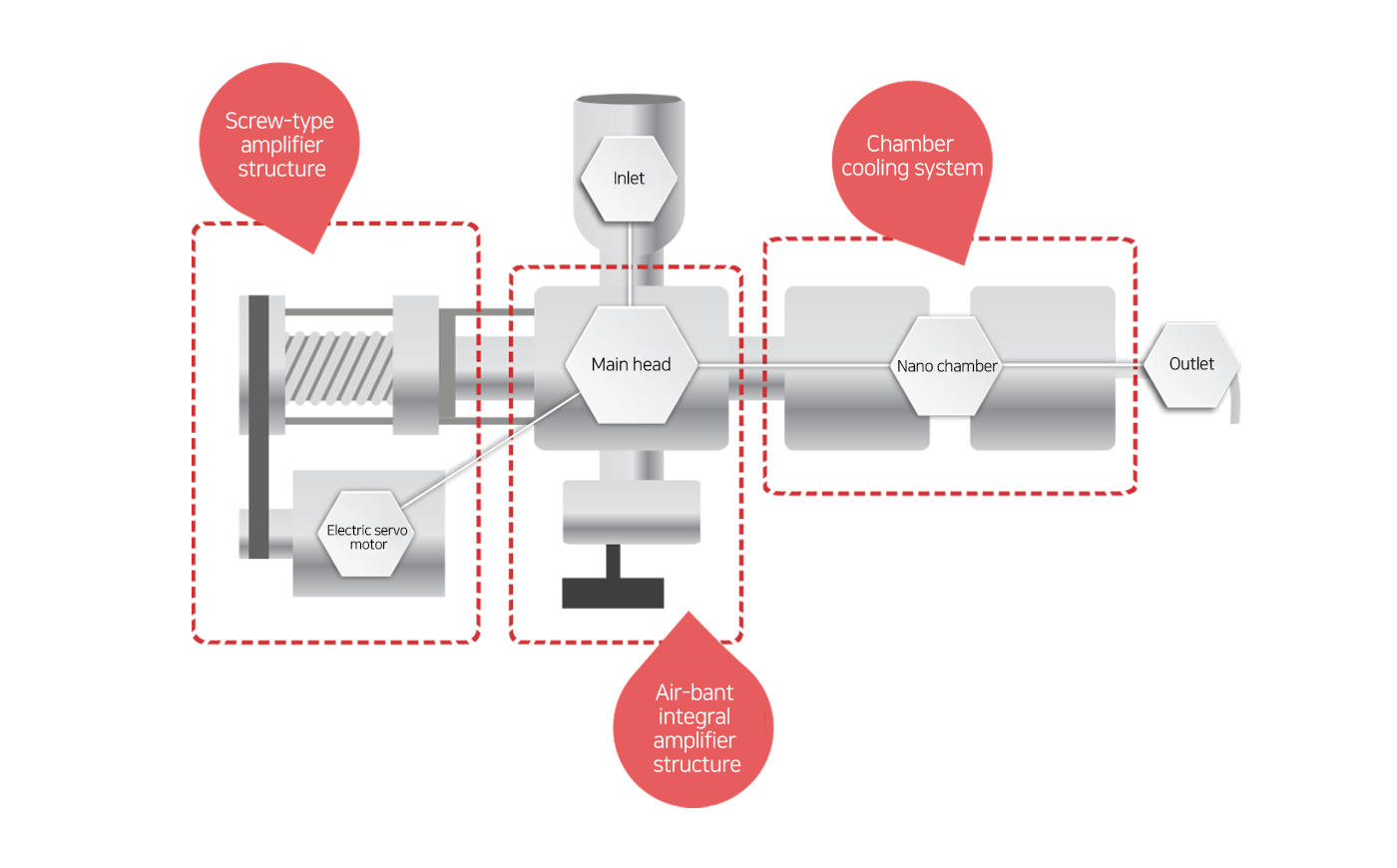

Increase the efficiency of an increase in pressure.

- Development of a screw-type amplifier that can generate high pressure (2,000 bar)

Material contamination prevention

- No leakage of hydraulic oil, etc. by adopting a power-operated system

Increase usability

- Electrically operated to simplify structure and eliminate additional facilities

- Massive reduction in volume and weight, using 220VAC as power

增加压力的效率。

-开发可产生高压(2000bar)的螺杆式放大器

防止材料污染

-采用动力传动系统,无液压油等泄漏

提高可用性

-电动操作,简化结构,减少额外设施

-体积和重量大幅减少,使用220VAC作为电源

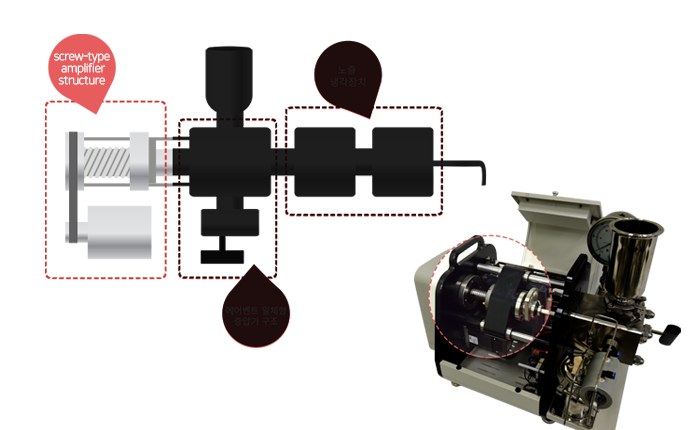

Increase the efficiency of an increase in pressure.

- Prevention of injection of raw material lines of non-pressure raw materials

Increase processing speed

- Easy to remove air from the pressurization chamber.

Increase usability

- No additional piping facilities, resulting in a significant reduction in volume.

- Use of high pressure (60,000 psi) needle valves to prevent material leakage

增加压力的效率。

-防止无压力原料的原料线注射

提高处理速度

-易于从加压室中取出空气。

提高可用性

-没有额外的管道设施,导致体积大幅减少。

—使用高压针阀(6000psi)防止物料泄漏

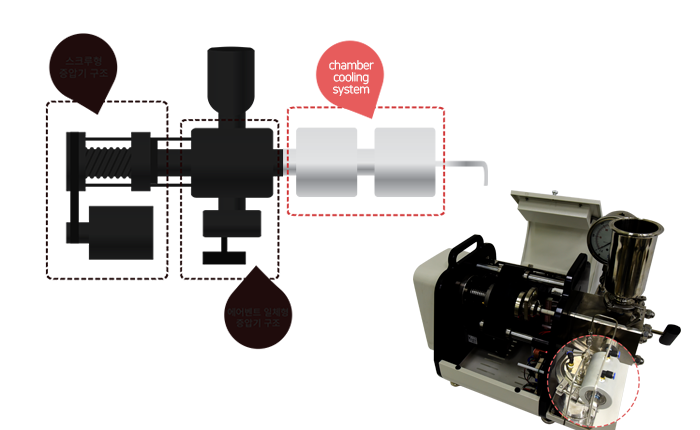

Preventing material deterioration

- Cool the nozzle to remove residual heat from the process

- Process can be applied to heat-sensitive materials

Increase usability

- Refrigerant and cooler available for your environment

- Simple structural design for easy coupling and separation

防止物质变质

-冷却喷嘴,从过程中去除剩余热量

-可应用于敏感材料

增加可用性

-制冷剂和冷却器可供您的环境

-简单的结构设计,便于耦合和分离

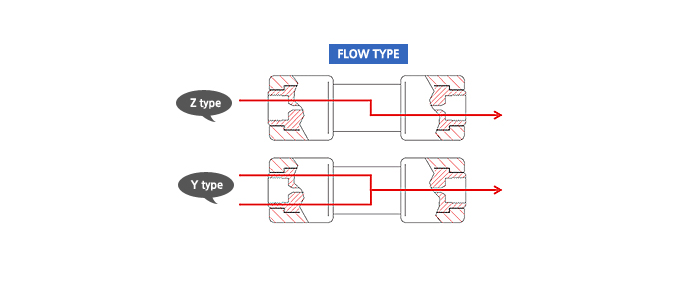

Interaction Chamber Type

Chamber Type

Z type : Suspension - Powder is recommended for dispersing and grinding on liquid, CNT, Aluminum, etc.

Y type: Emulsion - Liquid and Liquid, Recommended ex) milk, water, oil, etc.

相互作用腔类型

腔室类型

Z型:悬浮剂-推荐用于液体,碳纳米管,铝等的分散和研磨。

Y型:乳化液-液体和液体,推荐使用牛奶、水、油等。

ADD:Office Suite 29A, 3/F 23 Wharf Street London ,United Kingdom,SE83GG

ADD:Office Suite 29A, 3/F 23 Wharf Street London ,United Kingdom,SE83GG  WEB:www.aquariusscientific.com

WEB:www.aquariusscientific.com EMAIL:admin@

EMAIL:admin@