nG7400高压均质机

HOMOGENISING SYSTEMS

THE NEW HOME OF THE RANGE OF HIGH PRESSURE STANSTED HOMOGENISERS AND CELL DISRUPTER

"nm‑GEN‑7400" SERIES

ROBUST ‑ HIGH PERFORMANCE ‑ VERSATILE ‑ RELIABLE

HOMOGENISING SYSTEMS

STANSTED 高压均质和细胞破碎的新家庭成员

“nm -GEN- 7400”系列

健壮的-高性能-多功能-可靠

NANOPARTICLES

LIPOSOMES

MICROEMULSIONS

DEAGGLOMERATION

CELL RUPTURE

HP PASTEURISATION

纳米粒子

脂质体

微乳化

解聚松团作用

细胞破碎

高压杀菌

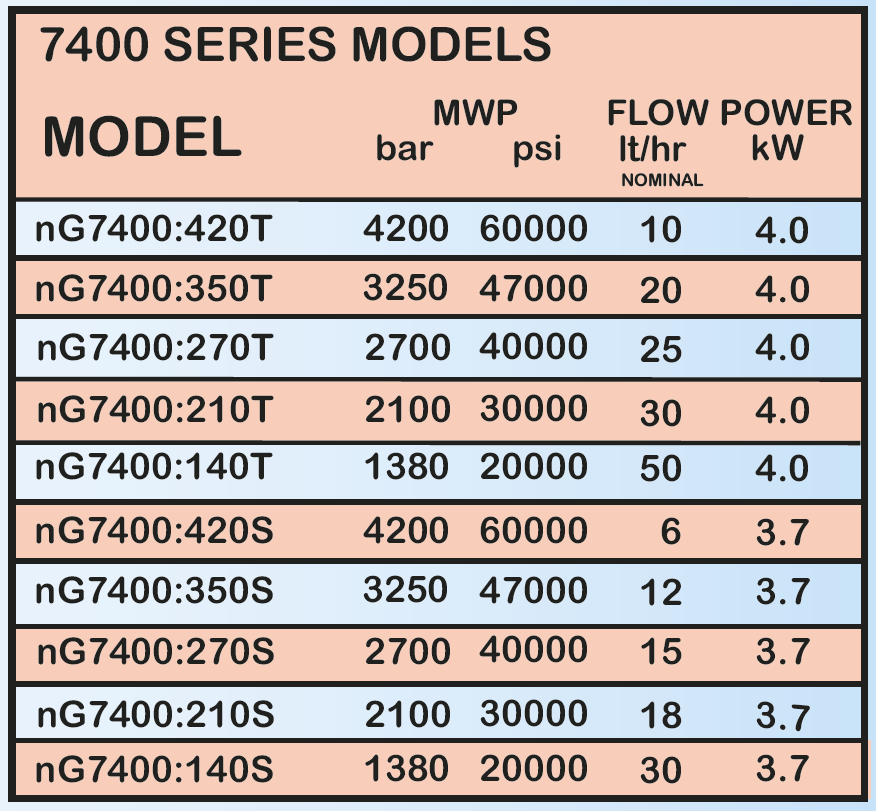

PRESSURES to 420 MPa 60,000 psi

FULLY CONTROLLABLE HOMOGENISING VALVES

MICRO CHANNEL DEVICE

BACK PRESSURE CONTROL

PROCESS TEMPERATURE CONTROL

EASY TO USE, CLEAN & MAINTAIN

REPRODUCIBLE RESULTS

SCALE UP

压力达到420MPa 60000psi

完全可控均质阀

微通道装置

背压控制

工艺温度控制

易于使用,清洁和维护

可重复的结果

可等量放大

The nm‑GEN 7400 Series "Hy‑Drive" series of homogenisation / cell rupture systems have been developed to meet the special requirements associated with biotechnology, chemical and pharmaceutical processing applications.

These systems complimented by smaller and larger models ranges offering processing from a few ml to many m3.

The nm‑GEN‑7400 Series is suitable for pilot and production applications.

The processing module is fully enclosed and the systems incorporate synchronised pair(s) of electro‑hydraulic high pressure intensifiers. These intensifiers feed the product at high pressure through a pressure processing head.

STANSTED high pressure homogenisers offer optimal processing by providing the user with the both Piston Gap homogenising valves or a Micro Channel Device (interaction chamber). Systems may be supplied with either or both options depending on the optimal choice the processing application.

Our piston gap devices offer market leading pressure capability to 420 MPa (60,000 psi , 4200bar) and the range includes a number of optimised geometric patterns and profiles for optimal performance in each application. These devices incorporate advanced hard materials for optimal wear resistance and are simple to clean and maintain.

Our micro channel devices provide multiple configurations including “Z” and “Y” paths a range of channels sized for control of shear rates Our assemblies incorporate hard wearing polycrystalline diamond channels and assemblies by be simply opened and reassembled for cleaning, inspection and refurbishment.

System control is provided through a dedicated PLC with HMI or IPC with touch screen interface. Systems are designed to provide compliance with cGMP & FDA‑GMP. Systems can be offered with IQ/OQ documentation, full materials certification. 21 CFR part 11 compliance can be provided . Production pharmaceutical applications are offered with finely polished finish on wetted surfaces, CIP and SIP capabilities Systems can be supplied with many options to allow custom configuration, so of these include

Back Pressure Module. A second stage homogenisation valve for us in the range 2‑20% of system maximum working pressure

Micro channel processing modules (for use up to 420 MPa (60,000 psi , 4200 bar)

Outlet Heat Exchanger. May be used to cool or heat product as required. Suitable for connection to external fluid circulation systems ‑20°C to +120°C

Inlet Heat Exchanger. May be used to cool or heat product as required. Suitable for connection to external fluid circulation systems ‑20°C to +120°C

Pressurised feed reservoir for use with high viscosity products.

The nm‑GEN‑7400 series is designed to provide the ultimate tool for R & D STANSTED and Production applications. The range has market leading pressure capability and construction incorporates the most advanced corrosion resistant materials and latest manufacturing techniques to ensure exceptional performance and reliability.

Attention to detail in design and manufacture ensures wetted surfaces our suitably polished, high pressure ram plungers and primary wear surfaces utilise super hard materials and ceramics. We retain full documentation for materials and instrumentation to ensure all appropriate documentation is available for system validation.

Our latest generate control interface combines a touch screen HMI / IPC and PLC combination with advanced control logic and safety interlocking for the system. Our menu driven user interface allows operator to easily set up and control processing primary processing parameters and to data log, record, store and retransmit process data for full integration into production lines.

nm - GEN 7400系列“Hy - Drive”系列均质/细胞破裂系统已开发,以满足与生物技术,化学和制药加工应用相关的特殊要求。

这些系统补充了较小和较大的模型范围,提供从几毫升到许多升的处理。

nm‑GEN‑7400系列适用于中试和生产应用。

处理模块是完全封闭的,系统包括同步对电液高压增强器。这些增强器在高压下喂入产品并通过高压处理头。

STANSTED高压均质机通过为用户提供活塞间隙均质阀或微通道设备(相互作用室)提供最佳处理。根据加工应用的最佳选择,系统可以提供其中一种或两种选择。

我们的活塞间隙装置提供市场领先的压力能力,达到420MPa (60000psi, 4200bar),该系列包括许多优化的几何图案和轮廓,可在每种应用中实现最佳性能。这些装置采用先进的硬质材料,具有最佳的耐磨性,易于清洁和维护。

我们的微通道设备提供多种配置,包括“Z”和“Y”路径,用于控制剪切速率的一系列通道。我们的组件包括耐磨的多晶金刚石通道和组件,只需打开和重新组装即可进行清洁,检查和翻新。

系统控制通过专用的PLC与人机界面或IPC与触摸屏界面提供。系统旨在提供符合cGMP和FDA - GMP。系统可以提供IQ/OQ文件,全材料认证。21 CFR第11部分的合规性可以通过以下方式进行验证。CIP和SIP功能系统可以提供许多选项,以允许定制配置,其中包括

整机背压模块。我们的二级均质阀在系统最大工作压力的2 - 20%范围内

微通道处理模块(用于高达420 MPa (60,000 psi, 4200 bar))

输出热交换器。可根据需要用于冷却或加热产品。适用于连接外部流体循环系统- 20°C至+120°C

进口热交换器可根据需要用于冷却或加热产品。适用于连接外部流体循环系统- 20°C至+120°C

用于高粘度产品的加压进料储罐。

nm‑GEN‑7400系列旨在为STANSTED和生产应用的研发提供终极工具。该系列具有市场领先的压力能力,结构采用最先进的耐腐蚀材料和最新的制造技术,以确保卓越的性能和可靠性。

对设计和制造细节的关注确保了湿润的表面,我们适当抛光的高压柱塞和主要磨损表面使用超硬材料和陶瓷。我们保留材料和仪器的完整文件,以确保所有适当的文件可用于系统验证。

我们最新的生成控制界面结合了触摸屏HMI / IPC和PLC结合先进的控制逻辑和系统的安全联锁。我们的菜单驱动用户界面允许操作员轻松设置和控制加工主要加工参数,并对数据进行日志,记录,存储和重新传输过程数据,以便完全集成到生产线中。

SERVICES

Electrical Supply

3.7‑4 kW systems

208‑460V 3ph 50/60Hz

Compressed Air (or nitrogen)

6 barg (75 psig) minimum

10 barg (150 psig) maximum

Cooling Fluid Drive System

Inlet connection G 1/2

Outlet connection G 1/2

0.2 barg (3 psig) minimum

3.0 barg (45 psig) maximum

+4°C minimum

+30°C maximum

Cooling / Heating Fluid

Outlet Heat Exchanger

(if required)

Inlet connection G 1/2

Outlet connection G 1/2

0.2 barg (3 psig) minimum

3.0 barg (45 psig) maximum

‑20°C minimum

+80°C maximum

PHYSICAL DATA

Width 1000 mm

Depth 800 mm

Height 2000 mm

Weight 475 kg ‑ 550

Depending on model

Process Connections

Inlet connection 3/4" Triclamp

Outlet connection 1/2" Triclamp

服务

电力供应

3.7 - 4 kW系统

208‑460V 3ph 50/60Hz

压缩空气(或氮气)

至少6巴(75磅压)

最大10bar (150 psig)

冷却液驱动系统

进气口连接g1 /2

出线连接g1 /2

最小0.2巴(3 psig)

3.0 barg (45 psig)最大值

+ 4°C最低

+ 30°C最大

冷却/加热流体

出口热交换器

(如果需要的话)

进气口连接g1 /2

出线连接g1 /2

最小0.2巴(3 psig)

3.0 barg (45 psig)最大值

- 20°C最低

+ 80°C最大

物理数据

宽度1000mm

深度800毫米

高度2000mm

重量475 - 550 kg

取决于模型

过程连接

入口连接3/4“Triclamp

插座连接1/2“Triclamp

STANSTED bench top systems complement the range of large scale systems. On left small scale production pharmaceutical production system with CIP and SIP capacility and HMI/PLC control with touch operation

STANSTED台式系统补充了大型系统的范围。左图为具有CIP和SIP能力的小规模制药生产系统,采用触摸操作的HMI/PLC控制

STANSTED pressure intensifiers. Graphic above (left) shows a typical STANSTED twin intensifier configuration. The graphic on the right shows the pressure vs time profile for a normal intensifier system and the bottom right the pressure vs time profile for a synchronised intensifier pair. Smooth pressure delivery reduces fatigue and ensures a more unitform STANSTED processing

STANSTED压力增强器。上图(左)显示了一个典型的STANSTED双增强器配置。右图显示了正常增强器系统的压力与时间曲线,右下角显示了一对同步增强器的压力与时间曲线。平稳的压力输送减少了疲劳,并确保更均匀的STANSTED加工