中试及生产型脂质体挤出器(可定制)

Liposomes can be classified by their size and lamellarity. These characteristics, along with lipid composition, determine the liposomes' stability and encapsulation efficiency.

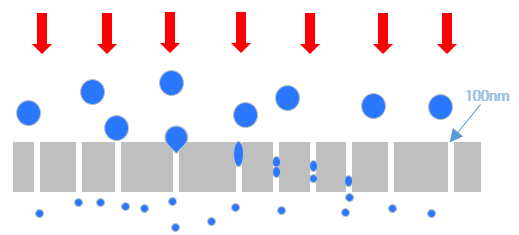

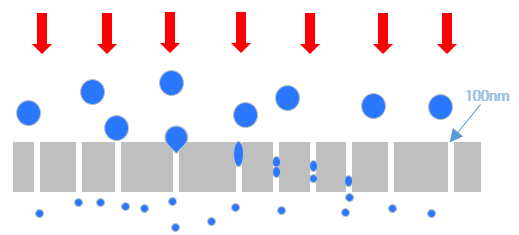

Multilamellar vesicles (MLVs) are relatively unstable, and they are not effective drug carriers due to their small core volume. This can be addressed by performing extrusion, whereby the MLVs are forced through polycarbonate filters with defined pore sizes. This disrupts the lipid bilayers of the vesicles, and if the force is strong enough, the MLV is completely torn apart, creating smaller fragments. These fragments immediately form as small unilamellar vesicles (SUVs) or large unilamellar vesicles (LUVs) at the other side of the membrane, with a diameter reflecting the pore size. The resulting unilamellar vesicles are more stable and retain high encapsulation capacity.

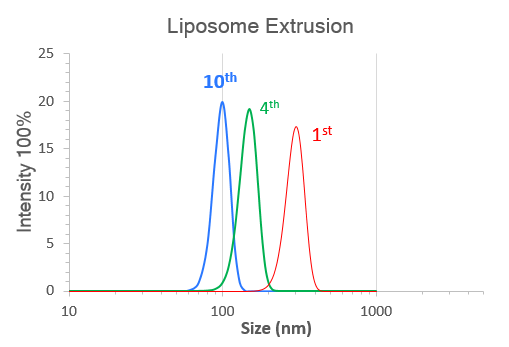

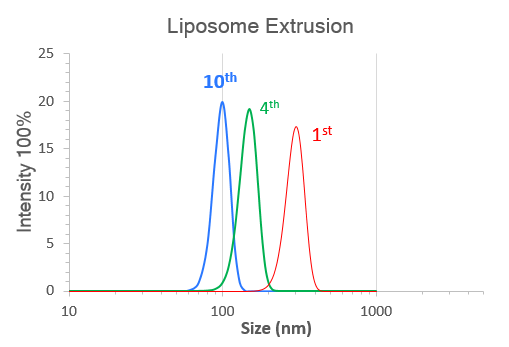

Additional passes through the membrane may further reduce the particle size and narrow the particle size distribution, as shown in Figure 2 (below).

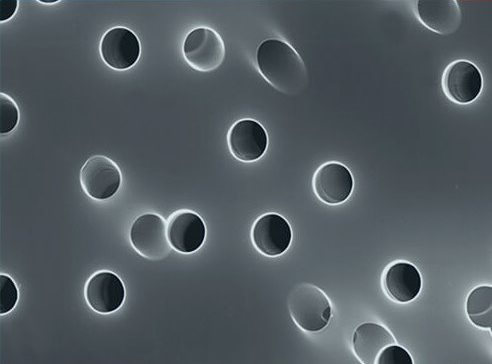

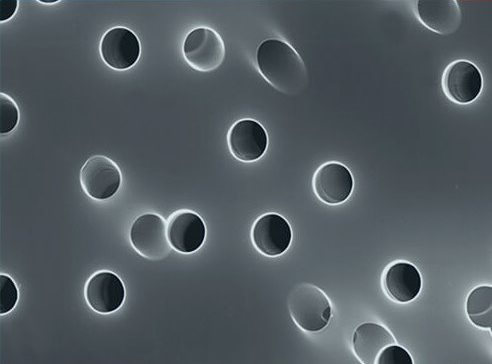

Liposome Membrane with 100nm Pore Size.

Schematic representation of the extrusion process.

Graph reflecting uniformity of size via repeated passages of the liposomes through the membrane

Figure 2. Forming unilamellar liposomes of the defined size by extrusion through a defined pore membrane filter.

LUVs may be the desired product of extrusion, as they have high encapsulation efficiency due to their large core volume. Producing these, rather than SUVs, can be achieved simply by increasing the filter pore sizes in the extruder membranes.

脂质体可根据尺寸和囊泡层数进行分类。这些特性与脂质组成共同决定了脂质体的稳定性和包封效率。

多层脂质体(MLVs)稳定性较差,且因其核心容积较小,并非有效的药物载体。通过挤压法可解决该问题——使MLVs强制通过特定孔径的聚碳酸酯滤膜。这一过程会破坏囊泡的脂质双分子层,当作用力足够强时,MLVs会被完全分解形成更小碎片。这些碎片在滤膜另一侧立即自组装成小型单层脂质体(SUVs)或大型单层脂质体(LUVs),其直径与滤膜孔径相对应。最终获得的单层脂质体具有更高稳定性且保持良好包封能力。

如图2(下图)所示,增加穿膜次数可进一步减小粒径并缩小粒径分布范围。

【图示说明】

100纳米孔径脂质体滤膜示意图

挤压过程原理示意图

脂质体多次穿膜后粒径均一化趋势图

图2. 通过特定孔径滤膜挤压形成规定尺寸的单层脂质体

LUVs因其大核心容积具备高包封效率,常作为挤压工艺的目标产物。只需增大挤压器滤膜孔径即可制备LUVs而非SUVs。

ADD:

ADD: TEL:+852 53995090(HK)

TEL:+852 53995090(HK) Mb

Mb